Development and exploratory design of textile based on tea, coffee, and yerba mate

Main Article Content

Abstract

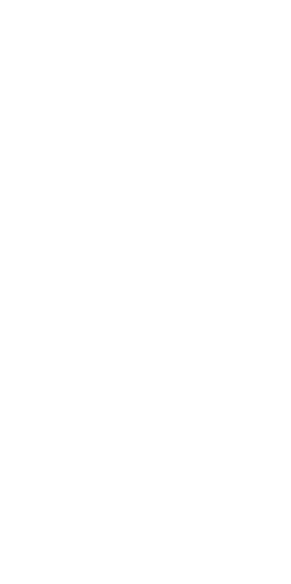

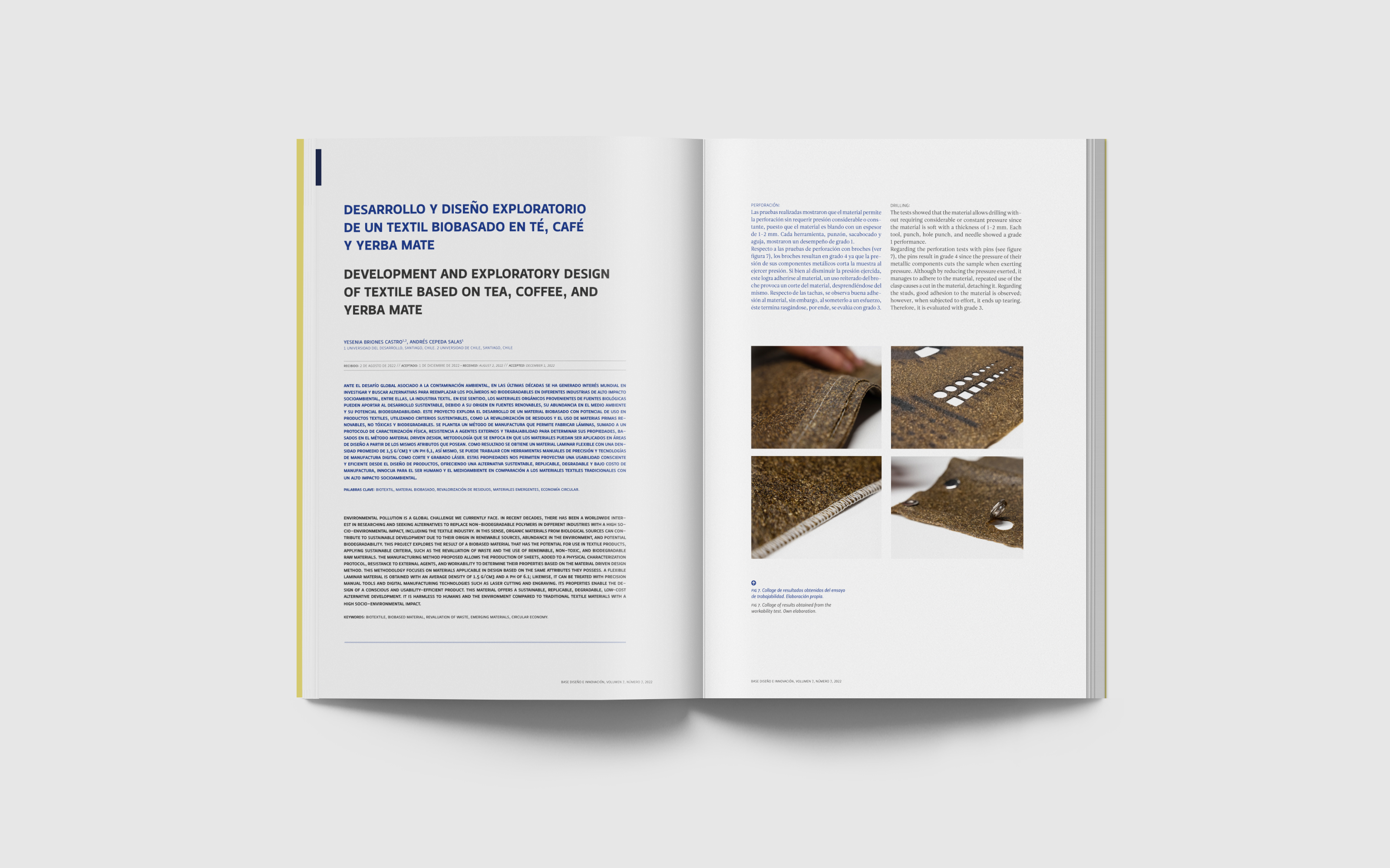

Environmental pollution is a global challenge we currently face. In recent decades, there has been a worldwide interest in researching and seeking alternatives to replace non-biodegradable polymers in different industries with a high socio-environmental impact, including the textile industry. In this sense, organic materials from biological sources can contribute to sustainable development due to their origin in renewable sources, abundance in the environment, and potential biodegradability. This project explores the result of a biobased material that has the potential for use in textile products, applying sustainable criteria, such as the revaluation of waste and the use of renewable, non-toxic, and biodegradable raw materials. The manufacturing method proposed allows the production of sheets, added to a physical characterization protocol, resistance to external agents, and workability to determine their properties based on the Material Driven Design method. This methodology focuses on materials applicable in design based on the same attributes they possess. A flexible laminar material is obtained with an average density of 1.5 g/cm3 and a pH of 6.1; likewise, it can be treated with precision manual tools and digital manufacturing technologies such as laser cutting and engraving. Its properties enable the design of a conscious and usability-efficient product. This material offers a sustainable, replicable, degradable, low-cost alternative development. It is harmless to humans and the environment compared to traditional textile materials with a high socio-environmental impact.

Article Details

References

Ananas-anam (2017). Piñatex I #MadefromPiñatex. New materials for a new world. Retrieved July 22, 2022, from https://www.ananas-anam.com

Arévalo, K. (1996). Elaboración de plásticos biodegradables a partir de polisacáridos y su estudio de biodegradación a nivel de laboratorio y campo [Doctoral dissertation, Universidad Autónoma de Nuevo León]. http://eprints.uanl.mx/4767/

Beall, A. (2020, July 12). Fast fashion is leading to a mountain of clothing being thrown away each year and has a huge impact on the environment, so can we turn our unwanted garments into something useful? https://www.bbc.com/future/article/20200710-why-clothes-are-so-hard-to-recycle

Bhardwaj, V. & Fairhurst, A. (2010). Fast fashion: Response to changes in the fashion industry. The International Review of Retail, Distribution and Consumer Research, 20(1) 165-173, https://doi.org/10.1080/09593960903498300

Biolab FAU. [@biolabfau] (2016). Laboratorio de Materiales Biobasados FAU. Instagram. Retrieved July 22, 2022, from https://www.instagram.com/biolabfau/

Cladophora. Cladophora by Malu Lücking. Retrieved July 29, 2022, from https://maluluecking.pb.design/cladophora

Demicheli, M. (1996). Plásticos biodegradables a partir de fuentes renovables. The IPTS Report, 10(1), 1-10. https://app.vlex.com/#vid/120222

Di Bartolo, A., Infurna, G. & Dintcheva, N. (2021). A Review of Bioplastics and Their Adoption in the Circular Economy. Polymers, 13(8), 1229. MDPI AG. https://doi.org/10.3390/polym13081229

Fab Textiles (2019). Coffee BIO-Leather Bag | FabTextiles. Retrieved July 29, 2022 from http://fabtextiles.org/coffee-leather-bag/

Fablab U. de Chile. (2012). FABLAB Universidad de Chile. Retrieved July 22, 2022 from http://www.fablab.uchile.cl/

FabLab UC. (2016). Laboratorio de prototipado digital Fablab UC. Retrieved July 22, 2022 from http://fablabuc.herokuapp.com/nosotros

Giaccardi, E. & Karana, E. (2015). Foundations of Materials Experience: An Approach for HCI. In Proceedings of the 33rd Annual ACM Conference on Human Factors in Computing Systems, 2447–2456. https://doi.org/10.1145/2702123.2702337

Gutiérrez, Q. (2021, october 1). Las 9 R de la Economía Circular. Sostenibilidad. Sostenible o Sustentable. Retrieved July 22, 2022, from https://sostenibleosustentable.com/es/economia-verde/9-r-de-la-economia-circular/

Karana, E., Barati, B., Rognoli, V., & Zeeuw van der Laan, A. (2015). Material driven design (MDD): A method to design for material experiences. International journal of design, 9(2), 35-54. http://hdl.handle.net/11311/979536

LABVA. (2022). Somoslabva [Colaboraciones]. Instagram. Retrieved July 29, 2022 https://www.instagram.com/somoslabva/

Lee, B. et al. (2018). Gelation of an alginate film via spraying of calcium chloride droplets. Chemical Engineering Science 183: 1-12. https://doi.org/10.1016/j.ces.2018.02.049

MaterialDistrict (2015, August 2). Rotterdam fruit leather. Retrieved July 22, 2022, from https://materialdistrict.com/material/rotterdam-fruitleather/

MaterialDistrict (2021, June 9). Berriestex – vegan leather. Retrieved July 22, 2022, from https://materialdistrict.com/material/berriestex-vegan-leather/

Materiom. (2022). Materiom.org. We're growing the regenerative materials economy. Retrieved July 22, 2022, from https://materiom.org/

Medina, E. (2022). Biología, Diseño y Naturaleza. Biology Studio. Retrieved July 22, 2022, from https://biologystudio.com.mx/

Muniyasamy, S., Mohanrasu, K., & Gada, A., Mokhena, T. C., Mtibe, A., Boobalan, T., Paul, V., Arun, A. (2019). Biobased Biodegradable Polymers for Ecological Applications: A Move Towards Manufacturing Sustainable Biodegradable Plastic Products. In S. ul-Islam Integrating Green Chemistry and Sustainable Engineering, 215-253. https://doi.org/10.1002/9781119509868.ch8

Niinimäki, K., Peters, G., Dahlbo, H., Perry, P., Rissanen, T., & Gwilt, A. (2020). The environmental price of fast fashion. Nature Reviews Earth & Environment, 1, 12. 189-200. https://doi.org/10.1038/s43017-020-0039-9

Project Pomace. (2022). Retrieved July 29, 2022, from https://pomace.nl/about/

Spora Biotech. (2022). Mycelium Mushroom Leather - Sporatex. Spora Biotech Plataform. Retrieved July 29, 2022, from https://www.sporabiotech.com/

Rodríguez, N.; McLaughlin, M. & Pennock, D. (2019). La contaminación del suelo: una realidad oculta. Organización de las Naciones Unidas para la alimentación y la agricultura (FAO). Retrieved July 22, 2022, from https://www.fao.org/3/i9183es/i9183es.pdf